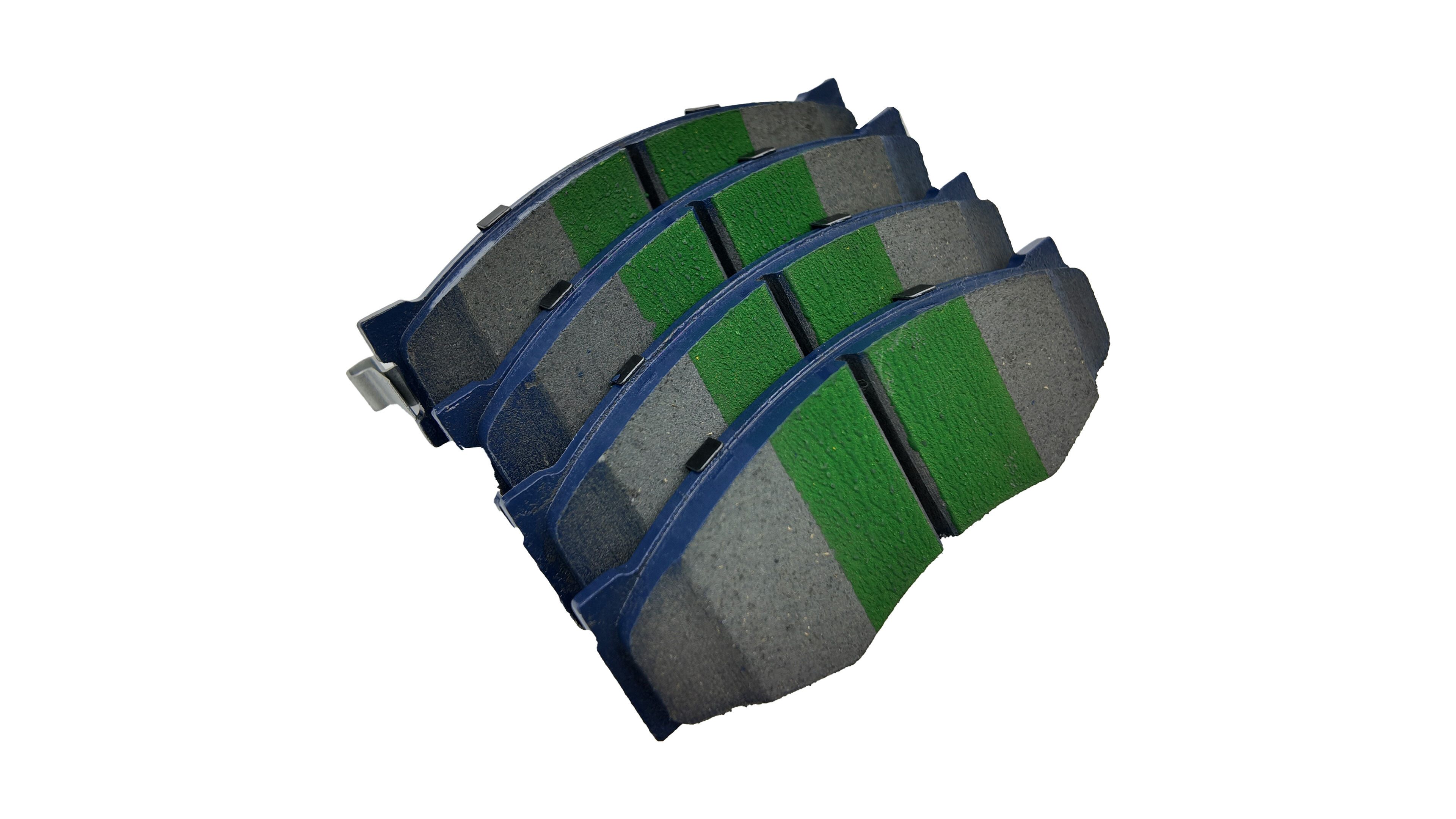

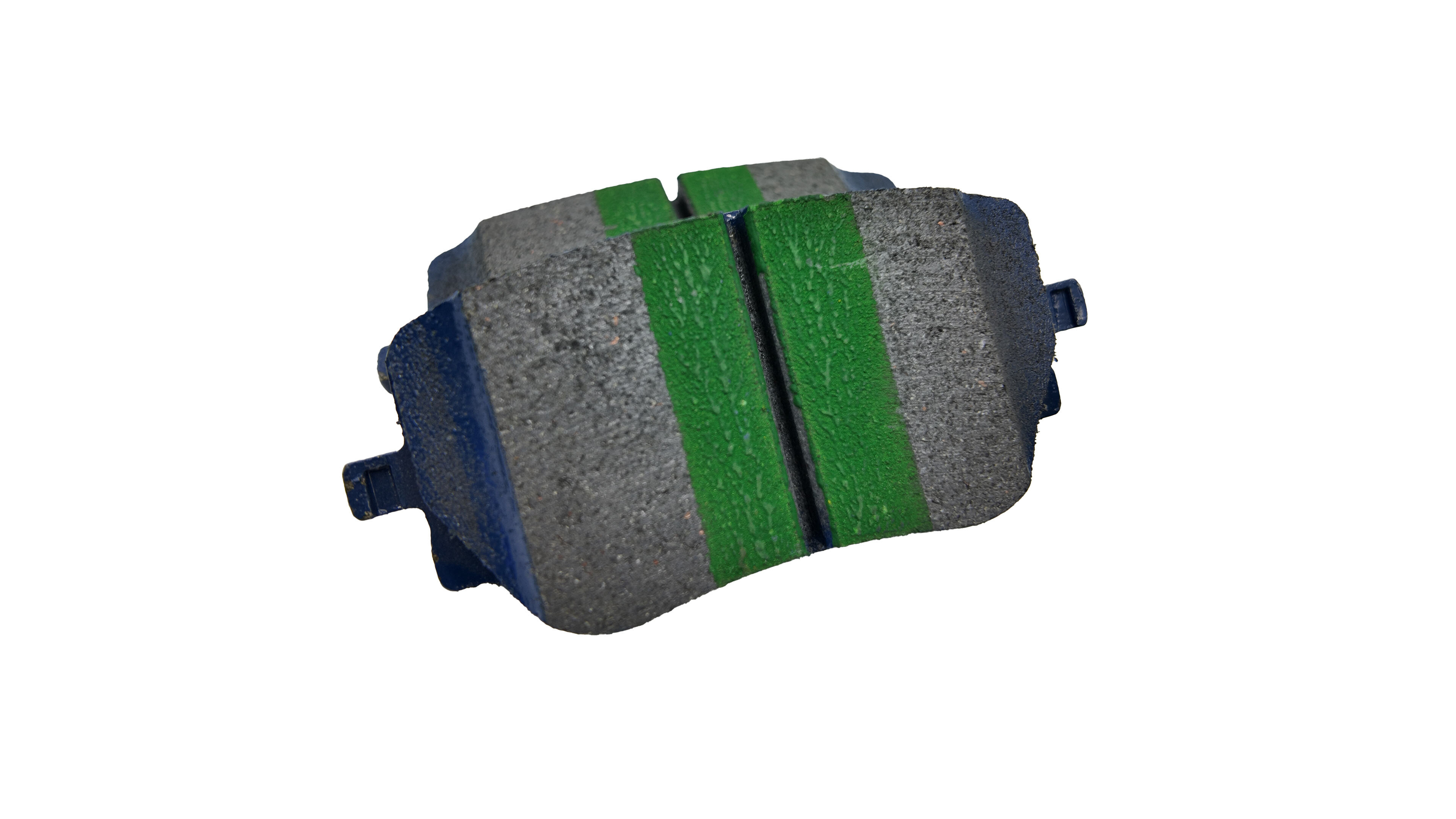

brake pad supplier

A brake pad supplier serves as a crucial link in the automotive supply chain, specializing in the manufacturing, distribution, and quality assurance of essential braking components. These suppliers maintain extensive inventories of brake pads designed for various vehicle makes and models, ensuring consistent availability and reliable performance. Modern brake pad suppliers leverage advanced manufacturing technologies to produce components that meet or exceed OEM specifications, incorporating the latest materials science developments for optimal friction coefficients and heat dissipation. They typically operate sophisticated testing facilities where products undergo rigorous quality control procedures, including thermal stress testing, wear resistance evaluation, and noise reduction verification. Additionally, these suppliers often provide technical support services, including fitment guidance, installation recommendations, and warranty coverage. Their product range typically encompasses different pad formulations, from organic and semi-metallic to ceramic compounds, catering to diverse driving conditions and vehicle applications. Many suppliers also maintain strategic partnerships with automotive manufacturers and distributors, enabling them to anticipate market demands and adapt their production accordingly.