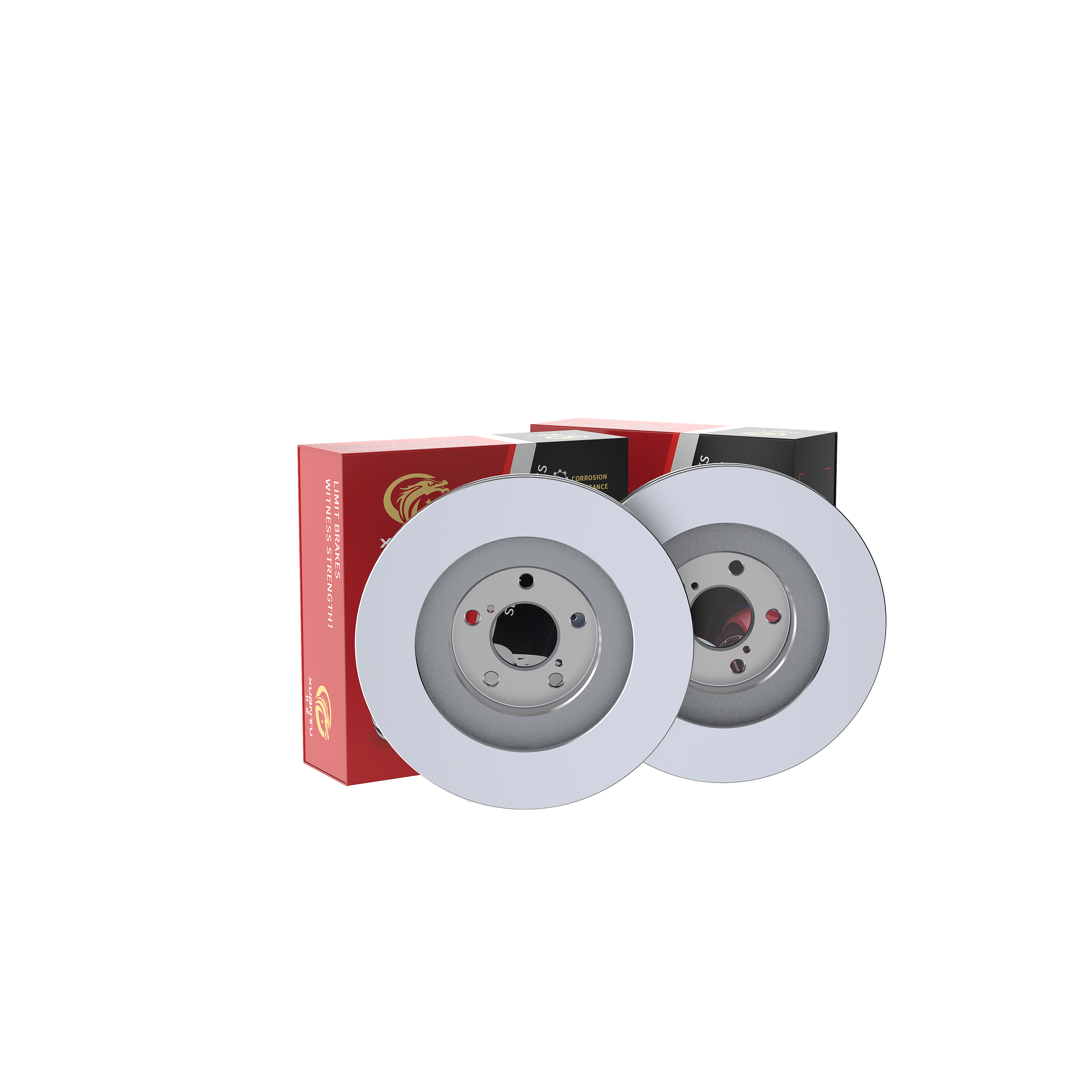

brakes and rotors

Brakes and rotors are fundamental components of a vehicle's braking system, working in precise harmony to ensure safe and effective vehicle deceleration and stopping. The brake system consists of brake pads that apply pressure to the rotors, which are flat, circular discs attached to the wheel hub. When the driver presses the brake pedal, hydraulic pressure forces the brake pads against the spinning rotors, creating friction that converts kinetic energy into heat energy, thereby slowing or stopping the vehicle. Modern brake rotors are engineered with advanced metallurgical compositions that optimize heat dissipation and durability. Many feature ventilated designs with internal cooling vanes that help maintain optimal operating temperatures during intensive use. The surface of quality rotors is precision-machined to ensure perfect contact with brake pads, while some premium models incorporate cross-drilling or slotting patterns to enhance performance in wet conditions and assist with heat dissipation. These components are essential in both everyday driving situations and high-performance applications, from daily commuters to racing vehicles. The technology continues to evolve with innovations in materials science and manufacturing processes, resulting in increasingly efficient and reliable braking systems.