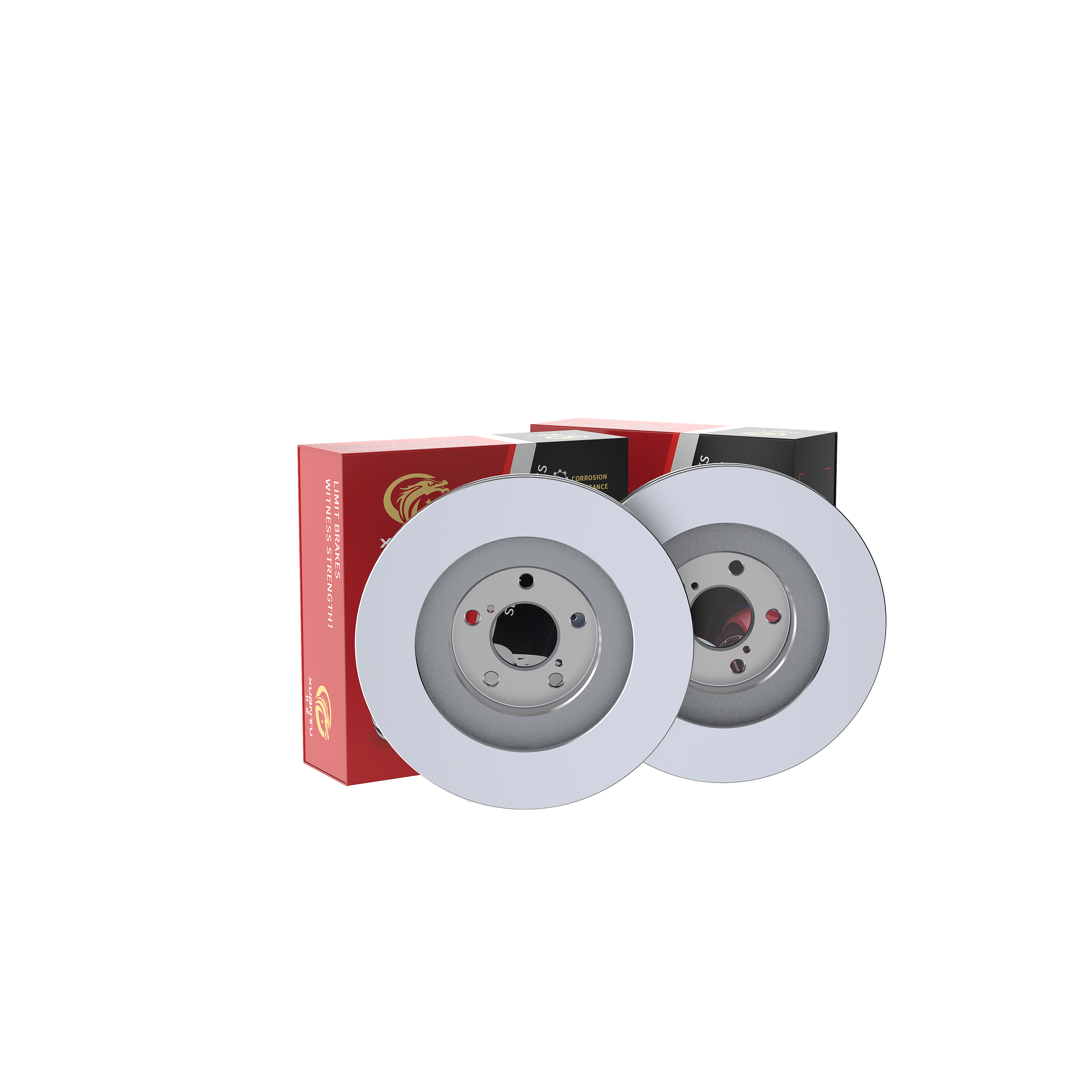

drilled and slotted rotors

Drilled and slotted rotors represent a significant advancement in brake system technology, combining enhanced performance with improved safety features. These specialized brake rotors feature strategically placed holes and slots across their surface, designed to optimize braking performance under various driving conditions. The drilling process creates holes that penetrate through the rotor, while slots are machined channels that run from the inner to outer edge. This unique design serves multiple purposes: it helps dissipate heat more effectively during intense braking situations, prevents brake fade by allowing gases and debris to escape, and maintains a clean contact surface between the brake pad and rotor. The construction typically involves high-grade cast iron or carbon-ceramic materials, processed using precision manufacturing techniques to ensure structural integrity while maintaining optimal weight characteristics. These rotors are particularly valuable in high-performance vehicles and demanding driving conditions, where consistent braking power and heat management are crucial. The technology has evolved to include various patterns and configurations, each optimized for specific driving requirements and vehicle types.