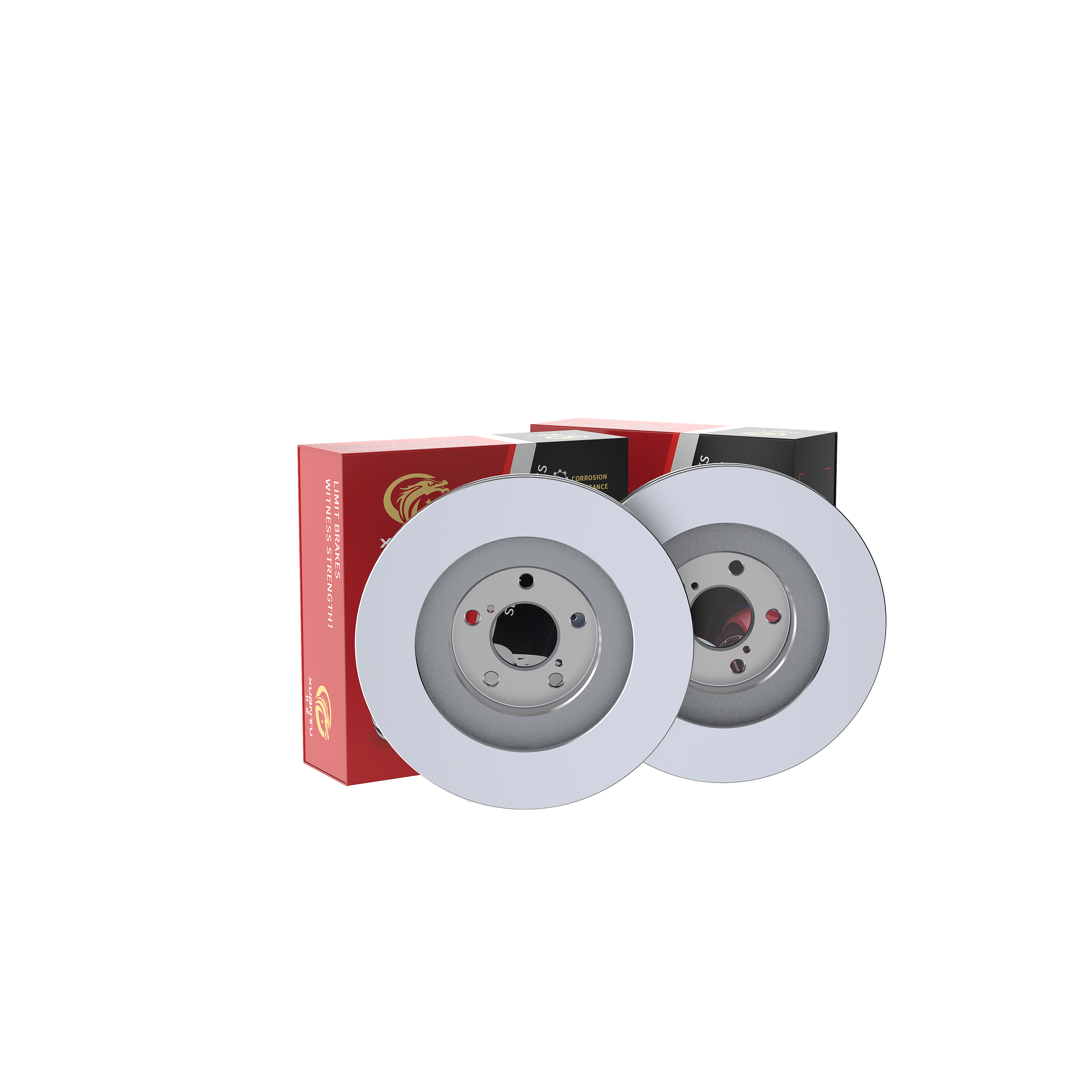

drilled slotted rotors

Drilled slotted rotors represent a significant advancement in brake system technology, combining two distinct features: drilled holes and machined slots across the rotor surface. These performance-oriented brake components are engineered to deliver superior braking performance under various driving conditions. The drilling and slotting processes create pathways that effectively dissipate heat, remove brake dust, and expel gases produced during the braking process. The strategically placed holes and slots work together to maintain optimal contact between the brake pad and rotor surface, ensuring consistent braking performance even under extreme conditions. These rotors are manufactured using high-grade materials and precision machining techniques to maintain structural integrity while providing enhanced cooling capabilities. The design allows for better water dispersal in wet conditions, reducing the risk of brake fade and maintaining reliable stopping power. Modern drilled slotted rotors often feature advanced coating technologies that protect against corrosion and extend the component's service life. Their application spans from high-performance vehicles to daily drivers seeking improved brake response and durability.