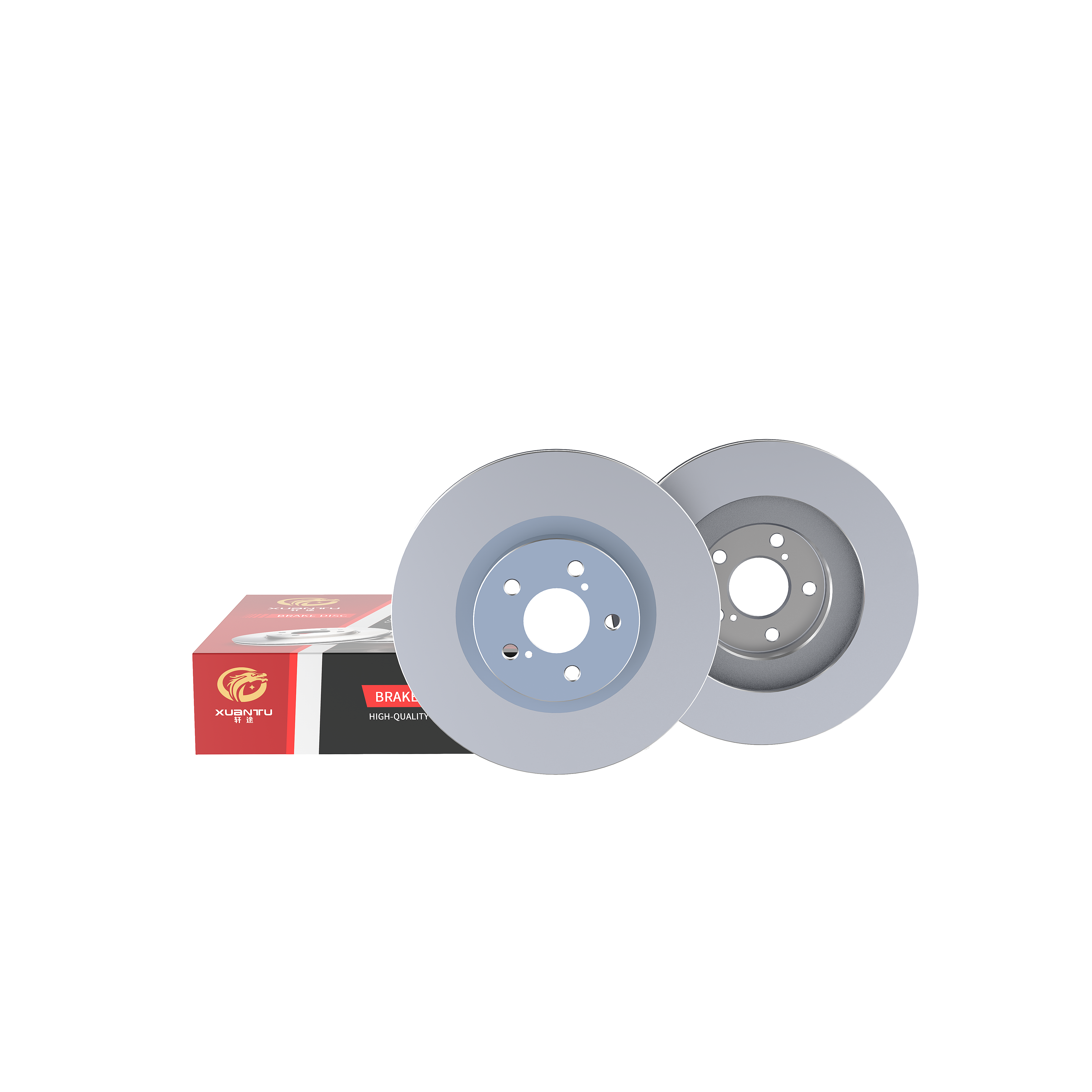

sdcx brake rotors

SDCX brake rotors represent a significant advancement in automotive braking technology, combining innovative design with superior performance characteristics. These rotors feature a unique cross-drilled and slotted pattern that maximizes heat dissipation while maintaining structural integrity. The precision-engineered surface design incorporates strategically placed holes and slots that work together to remove gas, dust, and water from the brake pad contact area, ensuring consistent braking performance in various weather conditions. Manufactured using high-grade carbon-enriched steel, SDCX rotors undergo a specialized heat treatment process that enhances their durability and resistance to warping. The rotors' distinctive design also includes curved vanes between the friction surfaces, creating a centrifugal pumping effect that forces cool air through the rotor, significantly reducing operating temperatures. These components are particularly well-suited for high-performance vehicles and demanding driving conditions, offering superior stopping power and fade resistance. Each rotor undergoes rigorous quality control measures, including computer-balanced testing to ensure optimal performance and minimize vibration. The application of a protective zinc coating helps prevent corrosion, extending the service life of the rotors while maintaining their attractive appearance.